In the past few decades, UV curing technology has shown its great application value in many fields, especially in the rapid curing of coatings, inks, adhesives and other products. In the traditional UV curing process, mercury lamps are widely used. However, because they contain mercury, they may cause harm to the environment and human health. Therefore, finding an environmentally friendly, efficient and long-lasting alternative has become a research hotspot. Among them, LED, as a new lighting technology, is gradually being used in the field of ultraviolet curing because of its environmental protection, high efficiency, and long life. This article will discuss the limitations of mercury lamps in UV curing and the application prospects of LEDs in UV curing.

1. Limitations of mercury lamps in ultraviolet curing

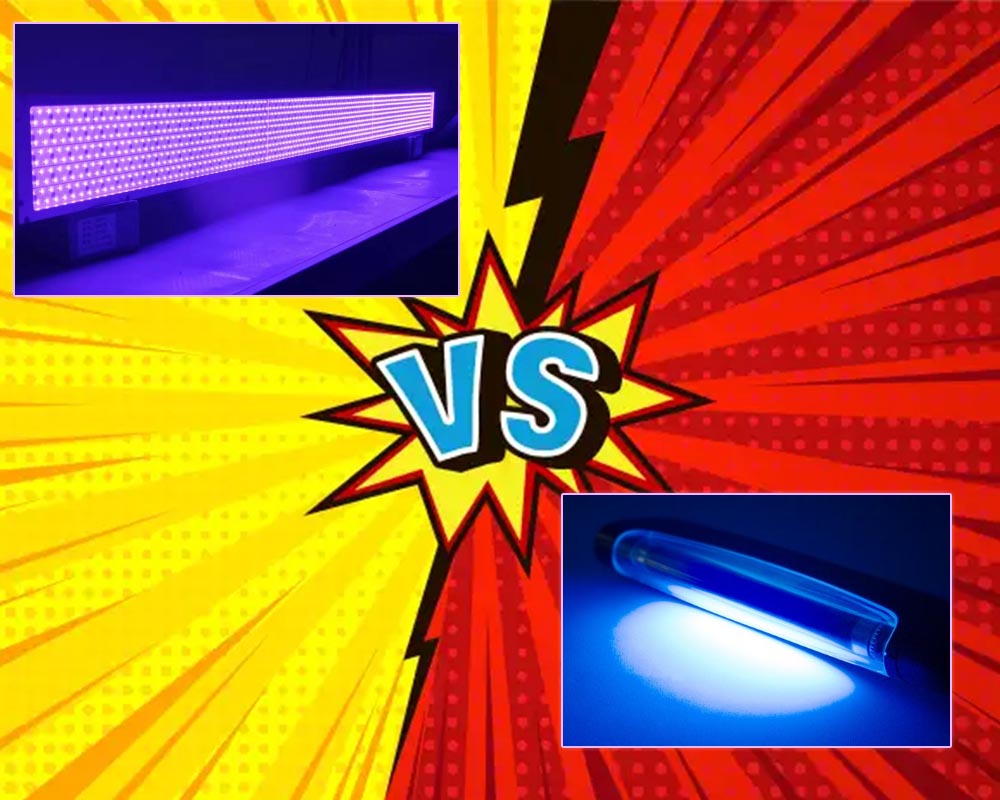

Mercury lamps are traditional UV curing equipment whose advantages include high brightness, long life, and suitability for a variety of curing applications. However, there are some limitations to the use of mercury lamps:

Environmental pollution: Mercury is a harmful heavy metal element, and mercury lamps will release mercury vapor during use. These mercury vapors may contaminate air, water and soil, posing a threat to the ecological environment and human health.

High energy consumption: The power of mercury lamps is usually high, resulting in a large amount of electricity consumption. This not only increases the economic cost of the curing process, but also exacerbates global energy shortages.

Thermal effect: The mercury lamp generates a large amount of heat energy when working, which may cause the temperature of the curing surface to increase, thereby affecting product quality and production efficiency.

2. Application prospects of LED in UV curing

As a new lighting technology, LED has the characteristics of environmental protection, high efficiency and long life, providing a new solution for ultraviolet curing.

Environmental advantages: LED does not contain harmful elements such as mercury, and its use will not pollute the environment. In addition, the cold light characteristics of LED prevent it from generating excessive heat during the curing process, thereby reducing the impact on the product itself and the surrounding environment.

Energy efficiency advantages: The energy efficiency of LEDs is much higher than that of mercury lamps, and the consumed electrical energy can be converted into light energy more effectively, thereby accelerating the curing reaction. This means that when achieving the same curing effect, the electrical energy required by LEDs is much lower than that of mercury lamps, thus reducing production costs.

Lifespan advantage: The lifespan of LEDs greatly exceeds that of mercury lamps, generally more than 50,000 hours. This means that using LED for UV curing can greatly reduce equipment maintenance and replacement costs and improve production efficiency.

Wavelength flexibility: The wavelength of LEDs can be adjusted by changing chip and packaging materials, which is very advantageous for curing applications that require specific wavelengths. For example, some materials may require short-wavelength UV light of 280 nanometers for curing, and LEDs can be customized to meet this need.

Although LED has significant advantages in UV curing, its current application in UV curing still faces some challenges. For example, the large light-emitting area of LED may lead to uneven light intensity distribution; in addition, the heat dissipation problem of LED also needs to be studied and solved in depth.

In general, LED has broad application prospects in UV curing. With the continuous advancement of technology and in-depth research, we have reason to believe that LED will play an increasingly important role in the field of UV curing in the future.

in conclusion:

This article discusses the possibility of replacing mercury lamps with LEDs in ultraviolet curing from two perspectives: the limitations of mercury lamps in ultraviolet curing and the application prospects of LEDs in ultraviolet curing. Mercury lamps are gradually being replaced by LEDs due to their limitations such as environmental pollution, high energy consumption and thermal effects. The advantages of LEDs are their environmental friendliness, high energy efficiency, long life, and wavelength flexibility, making them an ideal light source for UV curing. Although there are still some challenges in the application of LED in UV curing, with the continuous advancement of technology and in-depth research, we expect LED to play a greater role in the field of UV curing in the future.