Circuit boards are essential components of many electronic devices and systems. They consist of thin layers of copper and other metals that are etched or printed with conductive patterns that connect various electronic components. Circuit boards are often coated with a protective layer of solder mask, which is a polymer material that prevents corrosion, short circuits, and mechanical damage.

However, circuit boards can also suffer from various defects or damages that require repair. For example, some circuit boards may have broken or missing traces, pads, or vias that affect the electrical performance or functionality of the device. Other circuit boards may have cracks, scratches, or holes that expose the underlying metal layers to moisture, dust, or chemicals that can cause corrosion or oxidation.

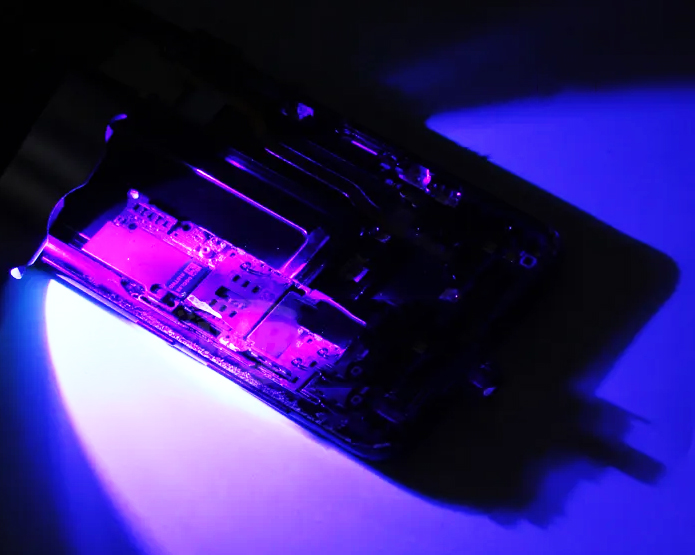

One way to repair circuit boards is to use UV LED curing technology. UV LED curing is a process that uses ultraviolet (UV) light-emitting diodes (LEDs) to initiate and accelerate chemical reactions that bond or harden materials such as adhesives, coatings, inks, and resins. UV LED curing has many advantages over traditional methods of curing such as heat, solvent, or moisture curing. Some of these advantages are:

- Faster curing speed and higher productivity

- Lower energy consumption and cost

- Lower heat generation and dissipation

- Higher control over the curing intensity and distribution

- Higher environmental friendliness and safety

- UV LED curing can be used for various applications in circuit board repair such as:

Curing solder mask: Solder mask is a green or black polymer material that is applied over the copper layer of a circuit board to protect it from corrosion, short circuits, and mechanical damage. Solder mask can be cured using UV LED lamps that provide a narrow beam of UV light that focuses on a small area. This allows for precise curing of small or localized areas or features such as bond lines, seals, gaskets, connectors, etc. UV LED curing also reduces the risk of overheating or damaging the circuit board or its components.

Curing conformal coating: Conformal coating is a transparent or translucent polymer material that is applied over the entire surface of a circuit board to provide additional protection from moisture, dust, chemicals, temperature changes, and mechanical stress. Conformal coating can be cured using UV LED lamps that provide a concentrated beam of UV light that covers a medium area. This allows for high-energy curing of medium-sized areas or features such as chips, capacitors, resistors, etc. UV LED curing also reduces the environmental impact and maintenance needs of the curing process.

Curing encapsulant: Encapsulant is a clear or colored polymer material that is applied over specific components of a circuit board to provide extra protection from moisture, shock, vibration, and thermal cycling. Encapsulant can be cured using UV LED lamps that provide a wide beam of UV light that covers a large area4. This allows for uniform curing of large areas or features such as chip-on-board (COB) or chip-on-flex (COF) printed circuit board applications. UV LED curing also enhances the flexibility and moisture resistance of the encapsulant.

UV LED curing is a fast, efficient, reliable, safe, and eco-friendly technology that can be used for various applications in circuit board repair. It can help improve the performance,quality, efficiency, reliability, safety, and environmental friendliness of circuit board repair processes. Some of the benefits of UV LED curing for circuit board repair are :

- They are entirely solid and lightweight, facilitating easy packaging and shipping of products

- They consume less energy and cost than heat-drying ovens or other curing methods

- They contain little or no volatile organic content, reducing the emission of harmful substances and odors

- They are more compact and flexible than broad-spectrum equipment, saving space and allowing for various curing configurations

- They eliminate mercury and ozone safety risks, as well as handling costs

UV LED curing is a promising technology that can offer many advantages for circuit board repair. However, it also requires careful selection and optimization of the UV LED lamps, the curing materials, and the curing parameters to achieve the best results. Therefore, it is important to consult with experts and manufacturers who can provide guidance and support for UV LED curing applications.

Our twitter:https://twitter.com/uvledcuringcn